Automatic Plugging Machines

Wood refining

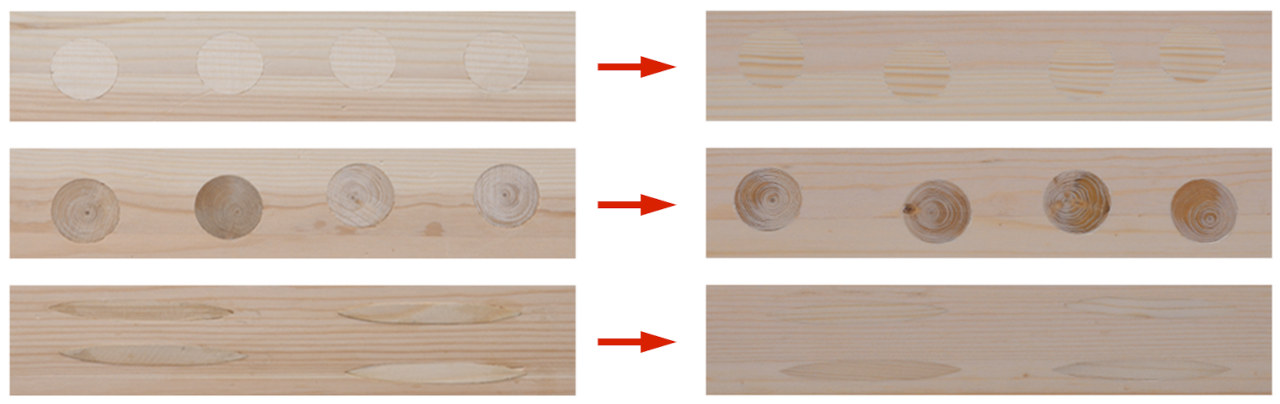

Improve your product quality and replace damaged areas such as knots, resin pockets and other wood defects in your solid wood panel.

Reduce your purchasing costs by sourcing solid wood panels with defects, which you can then refine using our machines.

With our automatic patching machines, you can give your workpiece quality, stability, durability and, last but not least, a better appearance. You can choose to patch knots with real knot dowels or patches from batten and/or replace resin galls with resin gall patches.

After sanding the patched solid wood workpiece, you will hardly see any traces of the patched areas. By varnishing the workpiece, the patched areas disappear.

Left: real knot plug

Middle: normal plug

Right: pitch pocket plug

al310 series

Automatic Knot Plugging Machine - Alomat AL310L-A

Automatic Plugging Machine - Alomat AL310A-HGF

hgf series

al100 series

Automatic Plugging Machine - Alomat AL100ASE-HGF

Our Automatic Plugging Machines at a Glance:

| Machine type | Cycle time [s] | Normal plugs from batten | Real knot plugs | Pitch pocket plugs | Number of processing options in one machine |

| AL310 | 1.8 | yes | 1 | ||

| AL310L-A | 2.2 | yes | yes | 2 | |

| AL310A-HGF | 3.5 | yes | yes | 2 | |

| AL100 | 3.5 | yes | 1 | ||

| AL100-ASE-HGF | 3.5 | yes | yes | yes | 3 |

| AL200 | 3.5 | yes | 2 | ||

| HGF310 | 3.5 | yes | 1 |