Drilling Modules

Our drilling modules are based on many years of experience and have been continuously developed and optimized based on individual customer problems. We offer a wide range of drive power, feed speeds, throttle devices, chip-out controls and fastening options, covering numerous areas of application.

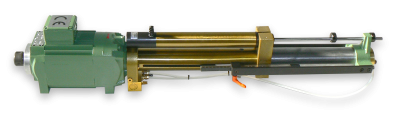

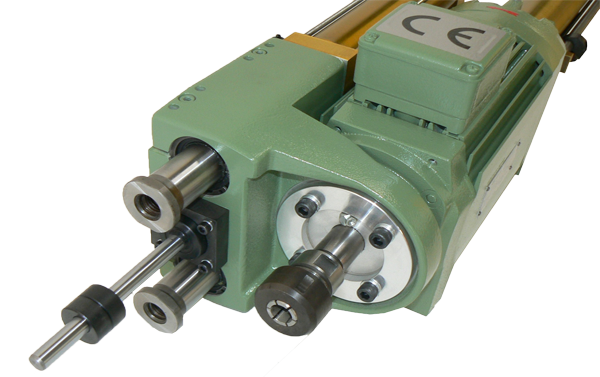

The special feature of our drilling modules is the thrust shaft, which extends from the rotor of the motor. Hence, not the entire drilling unit has to be moved for the drilling stroke, only the shaft is fed forward. A detailed description of our technology can be found at the bottom of this page.

Our drilling unit model series:

Model series RM

Model series RPM

Model series KBE

Carriage drilling module

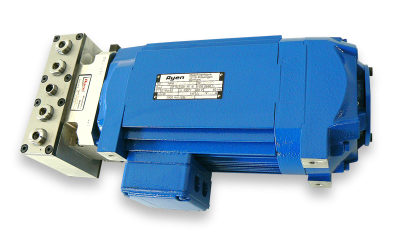

Model series RM

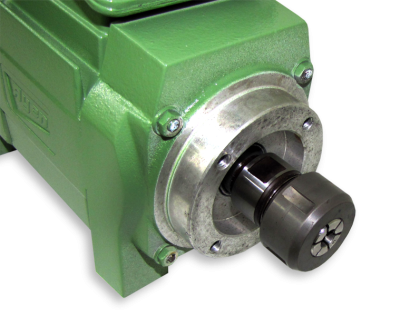

Our simple finned motors from the RM model series are available with different drive powers and have a collet chuck for tool holder as standard. They can be equipped with thrust shafts (motor spindles) of different lengths to achieve a drilling stroke of 70 mm to maximum 250 mm.

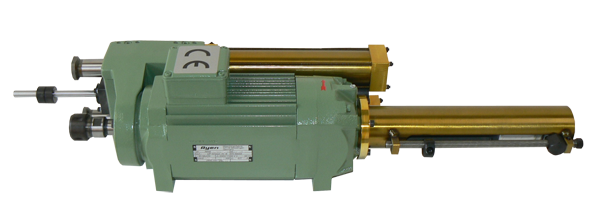

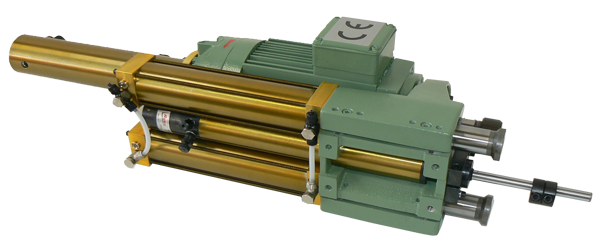

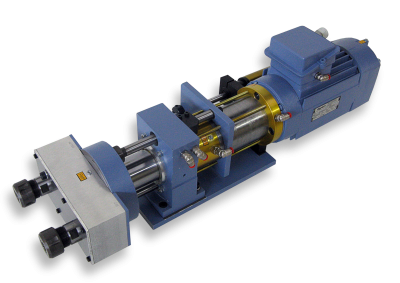

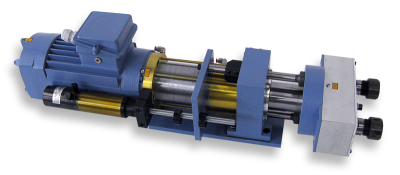

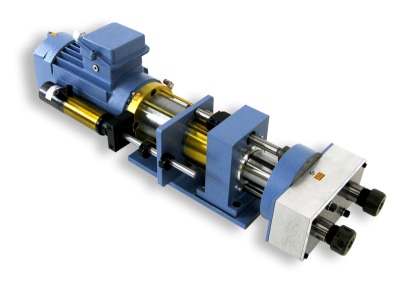

Model series RPM

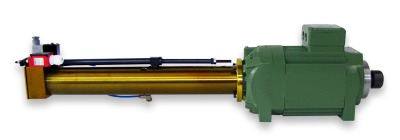

The electro-pneumatic thrust shaft drilling units of model series RPM are equipped with a pneumatic feed cylinder as standard and feature the thrust shaft principle described on this page. Depending on the application, they are available with 0.74 kW to 4.4 kW and in various designs to enable different types of fastening. The drilling stroke can also be selected via the motor spindle length (thrust shaft length) (88 mm | 150 mm | 200 mm | 250 mm).

The drilling units can also be equipped with the following control elements:

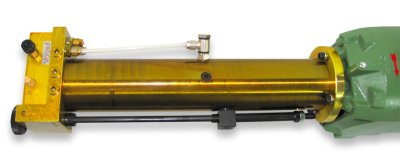

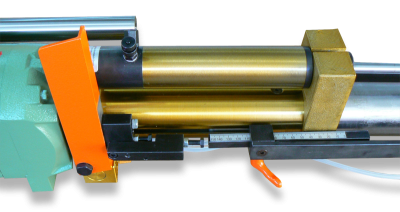

Oil brake (OZ)

The oil brake is used for load-independent, uniform feed movement. The range of the drilling stroke that is to be inhibited can be set individually, either to allow the feed speed of the motor spindle to take place at rapid traverse and to proceed carefully during machining, or to enable tear-free drilling through the workpiece. We manufacture our oil brakes ourselves and supply them in various designs to suit the required stroke and the existing machining task, which we will be happy to provide on request. They are robustly built, easy to maintain and simple to repair, which makes them durable and sustainable.

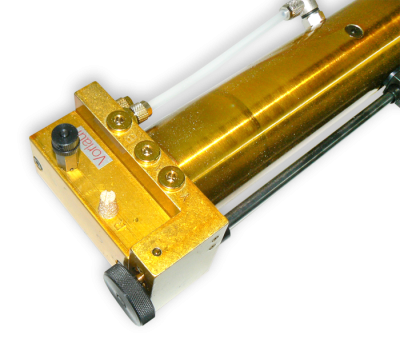

Reverse control valve (V)

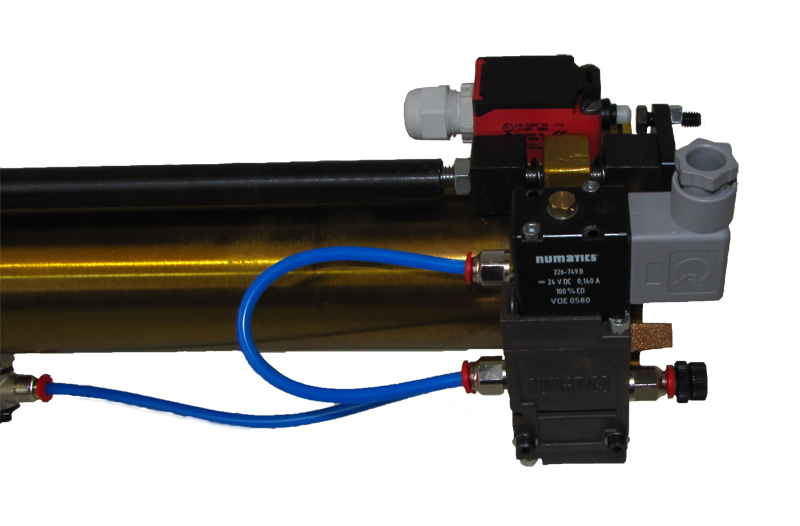

For pneumatic control of the drilling unit in an automated system with connections for start signal, feed speed and return speed.

Limit stop switch (E)

For drilling depth adjustment and reset

Solenoid valve and limit stop switch (EV)

For electrical control of the drilling unit in an automated system with limit switch for starting position and limit switch for drilling depth adjustment

Chip removal control (AV)

The RPM model series can be used to chip out deep holes either manually or with a path- or time-dependent chip removal control.

Other equipment options include end position damping, shaft sealing when machining from below and compliance with certain protection classes when using coolants.

........

Selectable conrol elements:

(click on the picture for a short description)

........

Electro-pneumatic drive or feed units RPM:

Select a drive unit from the RPM model series for your application. It enables the attachment of a drilling or milling heads.

........

Electro-pneumatic drilling unit RPM:

Drilling units configured to meet specific requirements with the help of our expert customer advisors.

Model series KBE

KBE is the short-stroke drilling unit model series, ideal for short machining paths. Their compact design stands for focused power.

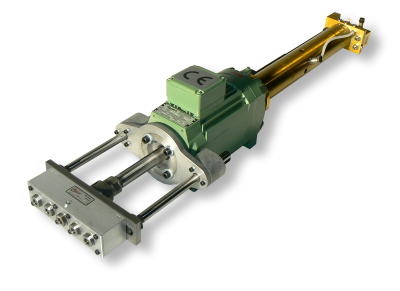

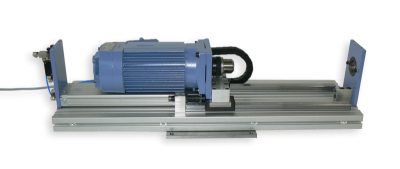

Model series BSE:

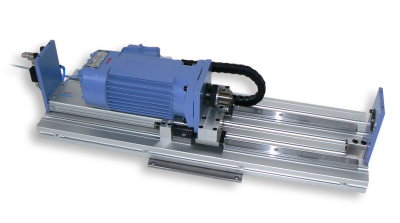

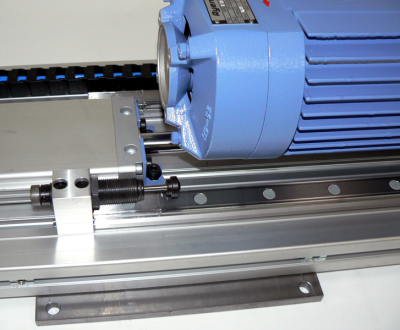

In addition to the described thrust shaft technology, the carriage drilling unit BSE can be flexibly moved on rails.

Technology of our Drilling Modules

Our electro-pneumatic drilling units are independent, self-contained units. This makes it possible to connect them individually or in groups to a special device or existing machines and production equipment according to your own plans. They are not tied to a machine design and can therefore be used elsewhere if the production process changes. Foot mounting and front flange mounting are available for installation.

The electro-pneumatic thrust shaft drilling unit from Ayen is made up of the following basic units:

Three-phase hollow shaft motor: narrow design (120 mm installation width), for the electromotive rotary actuator of the drilling spindle

Pneumatic feed unit: mounted on the motor in a tandem arrangement, for pneumatic or pneumatic-hydraulic feed of the drill spindle

Pneumatic or electro-pneumatic control unit: for controlling the feed drive

The motor power of our drilling unit series can be selected between 0.73 | 1.47 | 2.2 kW at a drill spindle speed of 2,800 rpm, depending on the application and the associated requirements. The feed force available at the drill spindle is approx. 1,470 N at an operating pressure of 6 bar.

The control system is designed so that the drilling units can be used both individually and as multi-spindle drilling devices, controlled together. A start signal from a foot-operated, hand-operated or electromagnetically operated 3/2-way valve is sufficient to start all drilling units in an assembly. The drilling spindle feed runs automatically, i.e. after actuating the start valve, the motor spindle extends to the set drilling depth and then returns to the starting position. You can choose between single drilling strokes or a continuous series of forward and return movements. The motor spindle feed path is infinitely adjustable up to the maximum possible stroke. Depending on your requirements, you can choose between 88 | 150 | 200 | 250 mm drilling stroke for your drilling unit.

The feed speed can be infinitely adjusted in both directions of movement by throttling the exhaust air. This is enabled by the double-acting compressed air cylinder of the pneumatic feed drive of the motor spindle. Due to the exhaust air throttling, the piston of the feed cylinder is braced between the incoming compressed air and the outflowing, throttled exhaust air, thus ensuring a uniform feed movement of the motor spindle. In many applications, this exhaust air throttling is sufficient. However, if a feed speed that is independent of strong load fluctuations on the drill spindle needs to be finely adjustable, the pneumatic feed cylinder is also equipped with an oil brake.

Please describe your drilling task so we can advise you on the motor power to be selected and the equipment of the drilling units with multi-spindle drilling heads, control valves, chip removal controls etc.. Also necessary information for a satisfactory consultation: type of wood, drilling depth, through-hole or blind hole, hole diameter and whether or not tear-out free operation is necessary on the exit side.