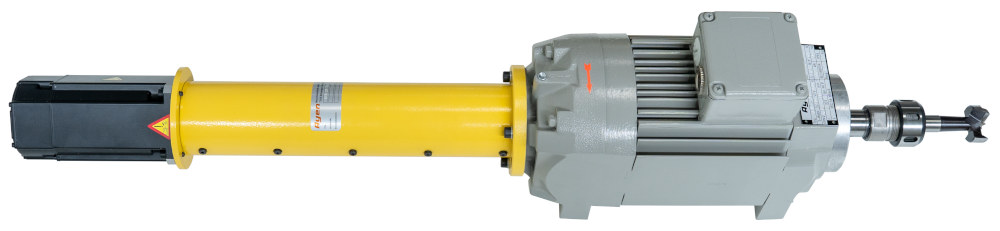

All-electric Thrust Shaft Drilling Unit - RESBOR

In regards to maximum energy efficiency with minimized conversion losses, designed as a stand-alone solution and suitable for use in automated systems, we have developed the all-electric RESBOR drilling module for and with our customers.

Thanks to its wide range of functions and simple operation, RESBOR outperforms conventional pneumatic drilling modules. All functions of our thrust shaft drilling modules, such as oil brake cylinder, chip removal device and other extensions, can be implemented within just one device.

RESBOR is flexible and future-proof: purchased today as a stand-alone solution - with extensive drilling tasks, even for small batch sizes quickly deployed - and used tomorrow for automated processing challenges in your company. This makes the purchase more cost-effective than specialized units for the respective task.

The NC-controlled servomotor drive regulates the drilling feed and ensures a controlled, uniform force development over the entire feed and drilling process. The 7'' touch color display allows straightforward operation. The respective workpiece surface can be taught in via the display at the touch of a button within no time, allowing the drill feed start position to be adapted to any workpiece thickness. In addition, the drilling depth is set by touch and an integrated chip-out control system is used to remove chips while drilling deeper holes. Both are included in the standard scope of programming. This means that larger drill diameters or different drill designs (spiral drills, Forstner bits, etc.) can also be used.

The slim design (120 mm wide) allows it to be used in confined spaces or installation situations. The motor spindle, which is pushed out of the drill motor with a stroke of 150 mm as standard, guides the drill through nearby parts of the workpiece without collision. Each RESBOR unit can be individually extended with, for example, multi-spindle drilling heads, additional linear axes or limit stop switches.

The CNC-capable control system also allows the use of several drive axes or the simultaneous use of up to 40 additional RESBOR units in a complex system.

Our competent consultants are happy to help you with individual solutions.

Benefits of RESBOR

Only electrical connection required

Energy saving

no conversion losses due to compressed air generation

Integrated regulation and control module

allows controlled, uniform force development during the entire drilling process

Space-saving design (slim construction)

Versatile and expendable

Extension options

Combine RESBOR with Ayen mult-spindle drilling heads

Move RESBOR on multiple, programmable linear axes

If you need an alternative drilling stroke, no problem!

Simultaneous application of up to 40 Ayen thrust shaft drilling units and/or several axes which can be controlled simultaneously

The optional CNC functionality allows complex automation tasks to be solved - with the help of our experts, we can solve any control challenge!

Technical data

Drilling motor parameters

Type RM22 with 1.5 kW, 230/400 V, 5.5/3.2 A

50 Hz, 2,800 rpm

Stroke

150 mm

Tool holder

Collet chuck device

Synchronous servo motor parameters

Operating voltage: 230 V

Motor voltage: 560/320 V

Nominal speed: 5,500/2,500 rpm

Nominal torque: 2.03 Nm

Current: 2.23 A

Digital power amplifier parameters

for AC-servo motors up to 320 V / 3 A

Peak output current: 9 A

50/60 Hz

PLC

for 1 to 40 drilling modules

7'' touch color display, resolution 1280 x 800

CPU: ARM

Ports: 1 x Ethernet / 1 x EtherCAT / 1 x USB 3.0

Standard programming

Manual operation for approaching and teaching of the workpiece surface

Automatic mode with option to controlled chip removal

Manual adjustment for drilling depth, drill feed speed and distance position