Automatic Plugging Machine - Alomat AL100ASE-HGF

Alomat AL100ASE-HGF at a glance:

3 in 1

Automatic plugging of wook defects with normal plugs and real knot plugs and pitch pocket plugs size G2

Cycle time 3.5 s

Choose plug type via foot valve

Workpiece clamping by elevating the working table

10 mm clamping stroke

15 mm bis 35 mm plug diameter

8 mm oder 10 mm plug thickness

Circumferencial gluing of normal plugs by means of glue rising grooves

Pitch pocket plugs of sizes G1 to G3 applicable

Normal plugs from batten

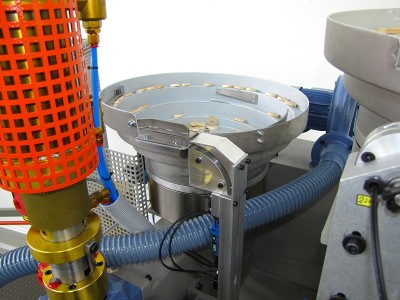

Real knot plugs stored in stacking magazine or spiral conveyor

Pitch pocket plugs stored in spiral conveyor

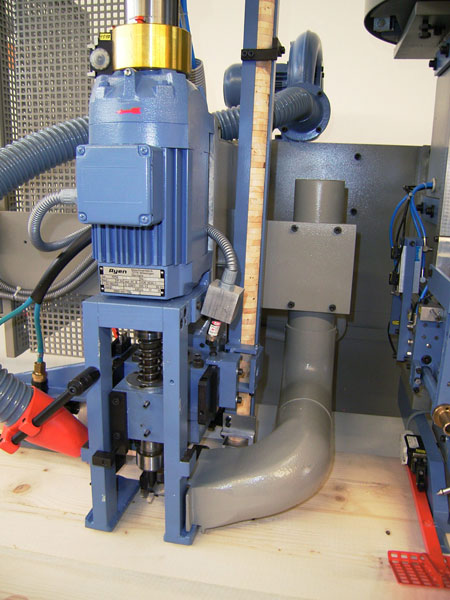

Our two-spindle automatic plugging machine Alomat AL100ASE-HGF offers the full range for wood refining. You can not only plug your workpiece with the commonly used normal plugs, but also with real knot plugs, which can be plugged with the help of the ASE knot plugging device. In addition, the Alomat AL100ASE-HGF offers the option of plugging pitch pockets via the second station using pitch pocket plugs size G2, which are stored as bulk material in a spiral conveyor. Both variants are used automatically without having to make any adjustments to the machine, simply by selecting the corresponding foot valve.

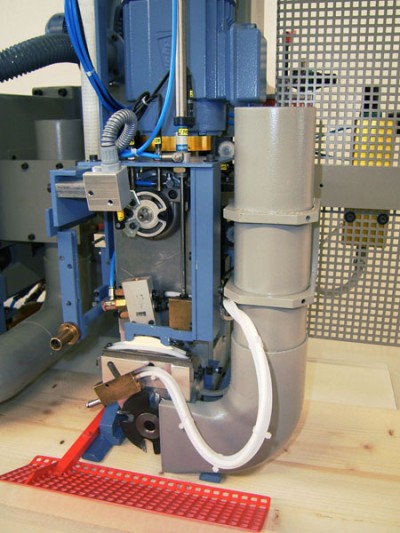

The workpiece is clamped by elevating the working table. The top of the workpiece is clamped and aligned in such a way that the normal plug is pressed in without any protrusion, regardless of the height tolerances of the workpiece and with a constant reference surface. Workpieces up to 140 mm thick can be clamped and plugged. The clamping stroke is 10 mm.

Glue rising grooves, which are automatically inserted on each normal plug, allow the glue to rise laterally along the circumference of the normal plug in glue channels towards the workpiece surface. This creates a tight fit of the normal plug (base and circumferencial gluing), which ensures the mechanical strength and quality of the workpiece due to the increased gluing surface and thus the reliability of the plugged areas compared to processes in which only the bottom is glued. In addition, there is no glue or air volume between the plug and the base of the drill hole. The normal plug is pressed in up to the bottom of the drill hole and lies on the same level as the workpiece surface. This prevents the plug from being drawn into the drill hole when the glue diffuses into the workpiece.

With the ASE and HGF variants for machines in the AL100 series, we offer the opportunity to refine your workpiece quickly, professionally and with a minimum of effort. This increase in wood quality and time saving enables you to work economically.

Alomat AL100ASE-HGF is available in 2 versions:

Version 1:

Real knot plugs stored in stacking magazine

Version 2:

Real knot plugs stored as bulk material in spiral conveyor

Add-on options for Alomat AL100ASE-HGF

All add-on options available for Alomat AL100 also apply here