Automatic Knot Plugging Machine - Alomat AL100

Alomat AL100 at a Glance:

Automatic plugging of wood defects with normal plugs from batten

Cycle time 3.5 s

Workpiece clamping by elevating the working table

10 mm clamping stroke

15 mm bis 35 mm normal plug diameter

6 mm bis 16 mm normal plug thickness

Circumferencial gluing of normal plugs by means of glue rising grooves

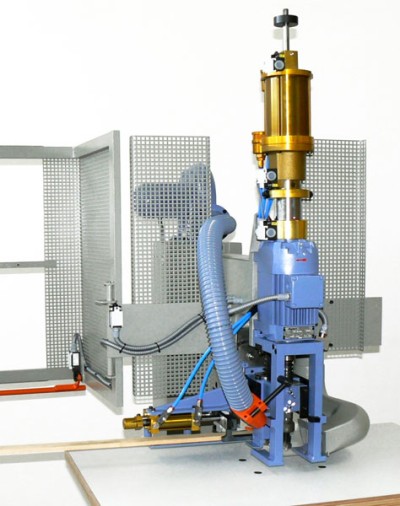

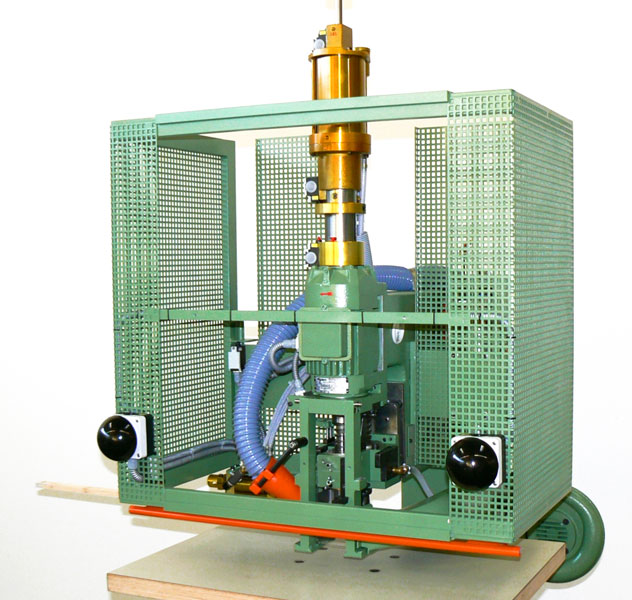

Our Alomat AL100 single-spindle automatic knot plugging machine allows for efficient plugging of knots, pitch pockets and swirls in wood. This refining of low-grade timber improves its quality and extends its range of application. Convince yourself of the advantages of this tried and tested technology and benefit from our years-long experience in the field of electro-pneumatically controlled automatic knot plugging machines, dating back to 1965.

The Alomat AL100 works with workpiece clamping by elevation of the working table. The upper side of the workpiece is clamped and aligned in such a way that the normal plug is pressed in without protrusion, regardless of the height tolerances of the workpiece and with a constant reference surface. Workpieces up to 140 mm high can be clamped and plugged. The clamping stroke is 10 mm.

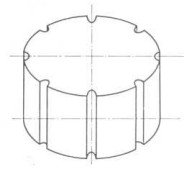

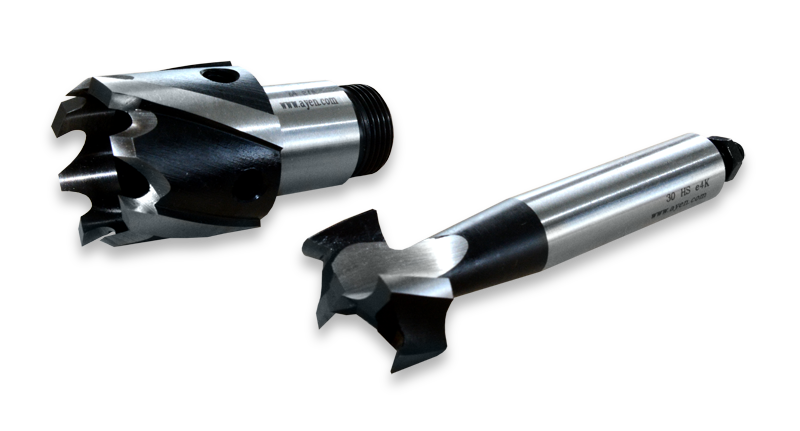

Glue rising grooves (see illustration), which are automatically inserted on each normal plug, allow the glue to rise laterally along the circumference of the normal plug in glue channels towards the workpiece surface. The glue rising grooves' depth is adjustable. This ensures that the gluing always withstands the upcoming stress on the workpiece and that your finished wood retains its high quality.

The AL100 creates a tight fit for the normal plug by gluing the base and its circumference and, thanks to the increased gluing surface, improves the mechanical strength and quality of the workpiece and thus the reliability of the plugged areas compared to processes in which only the bottom is glued. In addition, there is neither a glue pool nor an air volume between the normal plug and the base of the drill hole. The normal plug is pressed in up to the bottom of the drill hole and lies on the same level as the workpiece surface. This prevents the plug from being drawn into the drill hole once the glue diffuses into the workpiece.

Technical data

Tool drive power

1.5

kW

Tool drive rotation speed

2800

rpm

Cycle time

3.5

s

Air consumption per cycle

27

L

Normal plug diameter

15 | 20 | 25 | 30 | 35

mm

Normal plug thickness

6 | 8 | 12 | 16

mm

Workpiece clamping height

10 - 140

mm

Projection to drill

645

mm

Working table dimensions (width x depth)

1000 x 600

mm

Working height

840 - 980

mm

Necessary extraction capacity

360

m³/h

Extraction port diameter

86

mm

Compressed air connection

G 3/8

Compressed air system

6

bar

Operating pressure of glue container

3

bar

Glue container volume

1.4

L

Installation dimension length

1300

mm

Installation dimension width

1000

mm

Installation dimension height

2100

mm

Total machine weight

380

kg

Add-on options for Alomat AL100

Illustrations may differ from the original

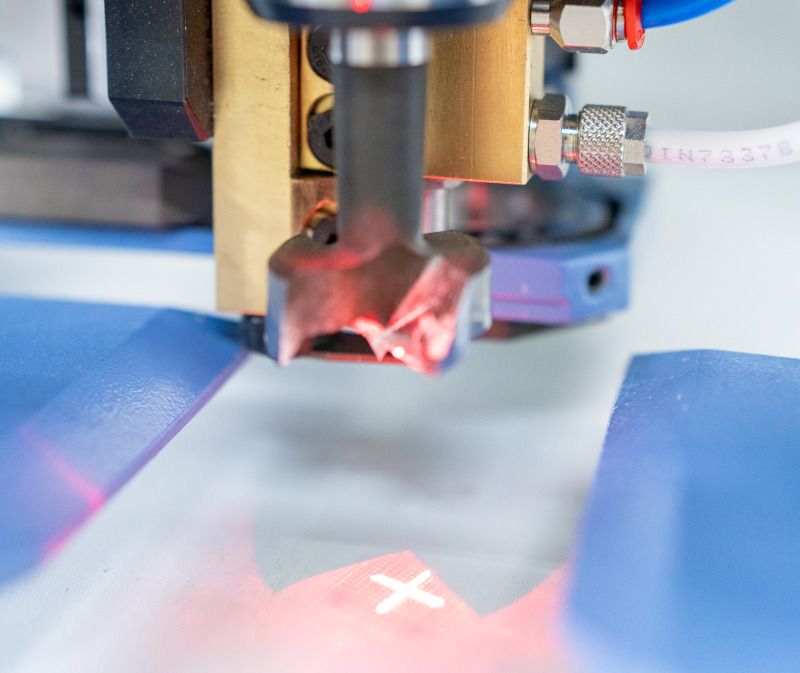

Target light

Our cross laser is used to optimally target wood defects. This means that the knot is in the center of the drill and can be completely replaced by the plug.

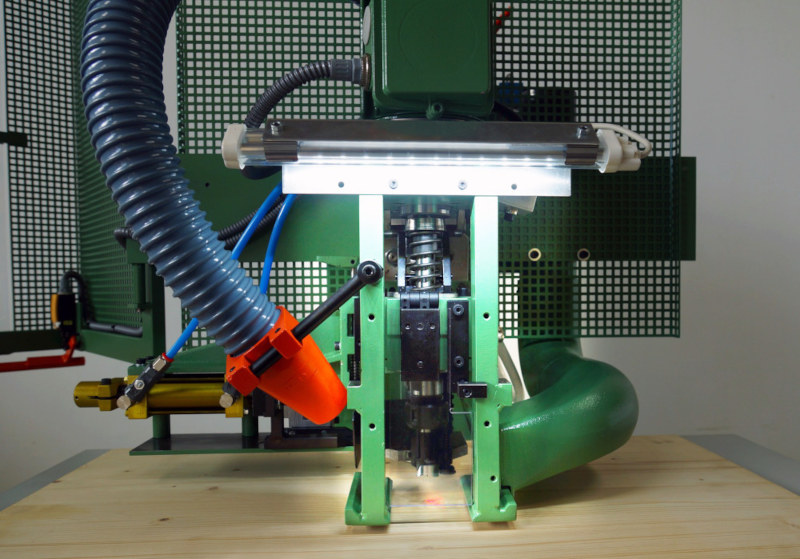

Workspace light

Even in poor lighting conditions, the LED workspace light guarantees illumination of the working area.

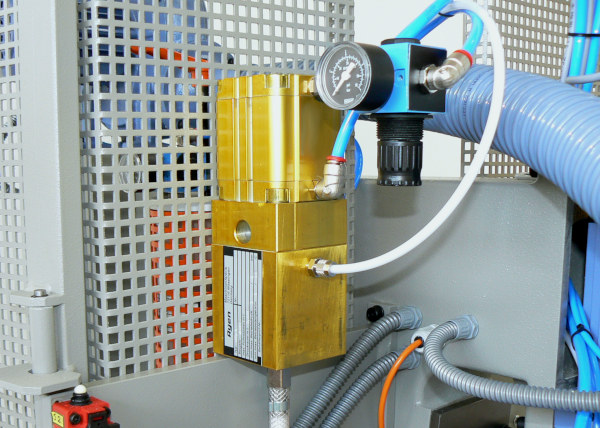

High-pressure gluing system HDL5

The high-pressure gluing sysem HDL5 enables the processing of glues with a viscosity of up to 6000 mPa*s. By increasing the glue pressure, the high-viscosity glue can be processed without any problems. This add-on is particularly necessary when using glues for outdoor use (glue class D4).

Automatic batten feed LZE-100/1

To save time, use our automatic batten feed LZE-100/1 , which greatly reduces the loading time of our automatic plugging machines. The battens required for the production of the normal plugs are kept in stock in the stacking magazine and are automatically separated after each batten ends and pushed to the starting position.

Batten length: 975 mm - 1005 mm

Batthen height: 6 mm - 16 mm

Batten width: 20 mm - 45 mm

Duration for batten change: 6 s

Two-hand release

The two-hand release of our Alomat AL100 is designed to fully protect your employees and prevent accidents caused by incorrect operation. This additional protection to the standard safety bar further increases operator safety minimizing the risk of entering the working area of the machine.

Accessories for Alomat AL100

Drilling tool

Tool holder of drill: cylindrical shaft Ø 16 mm with adjustment screw M6 | material HSS

Milling tool

Tool holder of milling tool: M22 x 1,5 | material HSS