Groove Milling Machine with Glue Application - HGF325

HGF325 at a Glance:

Automatic milling and glue application of elongated defects

Short cycle time of 5 s

Simple and trouble-free operation

No additional time needed for gluing

Subsequent, manual insertion of the mending strip

Workpiece clamping and pressing-in the plugging rod by lowering the unit

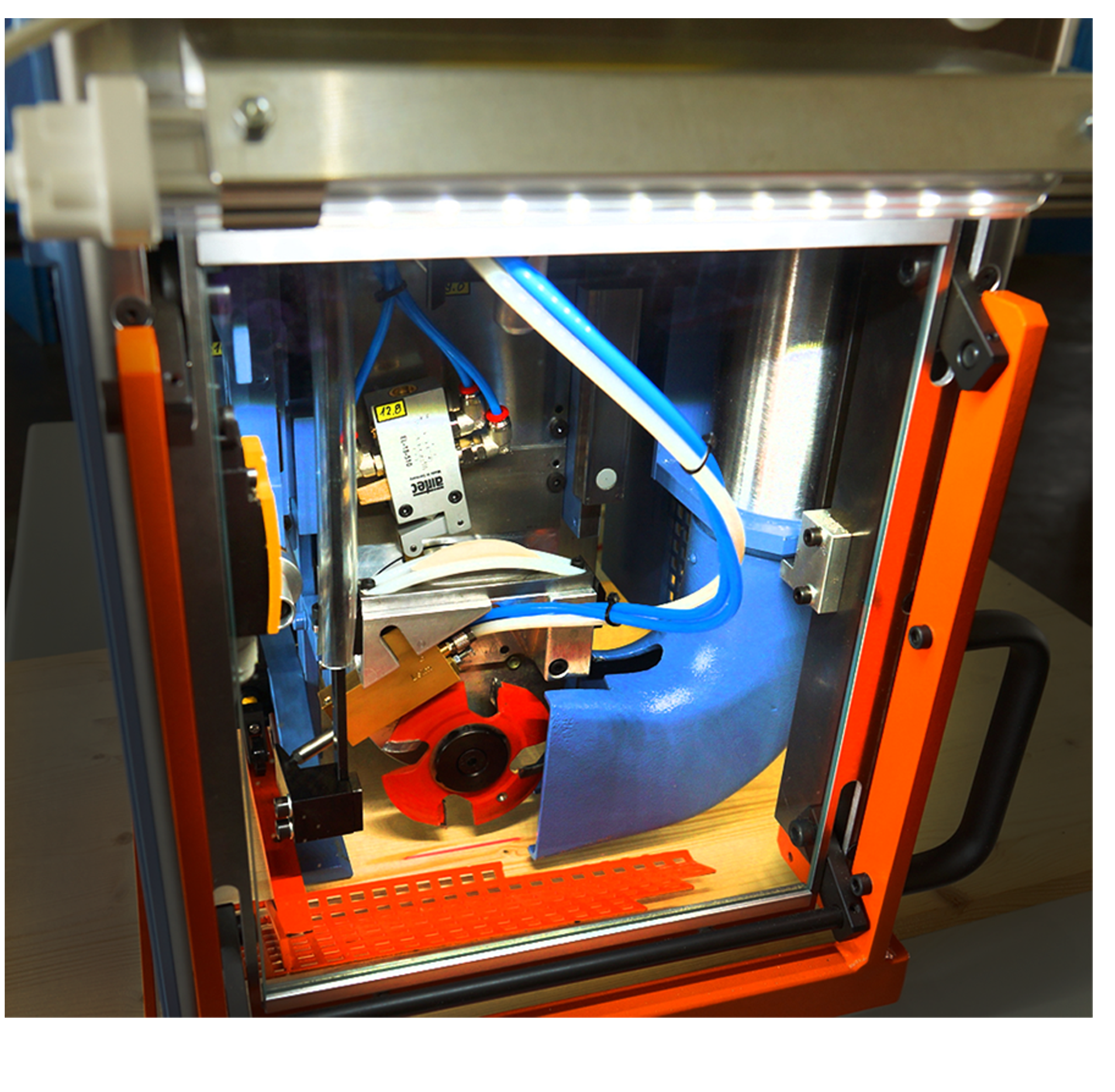

With the HGF325, we have developed an automatic plugging machine that repairs elongated defects in wooden workpieces: cracks, piths, pitch pockets, bark edges, small wood defects, mechanical damage to lamella edges or poor glue joints... no problem for the HGF325, which can be used to process both lamello minispot plugs and plug rods. The damaged area is milled out and then glued in just one clamping operation.

The HGF325 works with workpiece clamping by lowering the unit. The advantage of this method: The height of the working table is not changed; the operating height always remains constant, regardless of the workpiece height. This also allows problem-free processing of long workpieces. Both the clamping stroke and the workpiece thickness compensation are performed from above. For this purpose, the processing slide (incl. drilling and milling unit, glue injection device and feed cylinders) is lowered.

The side feed is 320 mm for plugging rods with a nominal length of 250 mm (total length approx. 320 mm, width 8 mm, height 13 mm); glue is applied to the groove synchronous to the side feed. The plugging rod is then placed manually in the glued groove and pressed into the groove by lowering the unit. The cycle time for this is approx. 5 seconds.

Technical data

Tool drive power

1.5

kW

Tool drive rotation speed

2800 - 5000

rpm

Feed motor power

0.65

kW

Cycle time

5

s

Air consumption per cycle

4

L

Plugging rod (h x w x l)

13 x 8 x 250

mm

Side feed length

320

mm

Workpiece clamping height

10 - 170

mm

Projection to cutter

650

mm

Working table dimensions (width x depth)

1000 x 600

mm

Working height

900

mm

Necessary extraction capacity

230

m³/h

Extraction port diameter

63

mm

Compressed air connection

G 3/8

Compressed air system

6

bar

Operating pressure of glue container

3

bar

Glue container volume

1.4

L

Installation dimension length

1330

mm

Installation dimension width

1000

mm

Insallation dimension height

2115

mm

Total machine weight

490

kg

Add-on options for HGF325

Illustrations may differ from the original

Target light

The line laser is used to optimally target the wood defect or pitch pocket. This places the defect on the center line of the cutter for it to be completely replaced by the pitch pocket plug.

Workspace light

Even in poor lighting conditions, the LED workspace light guarantees illumination of the working area..

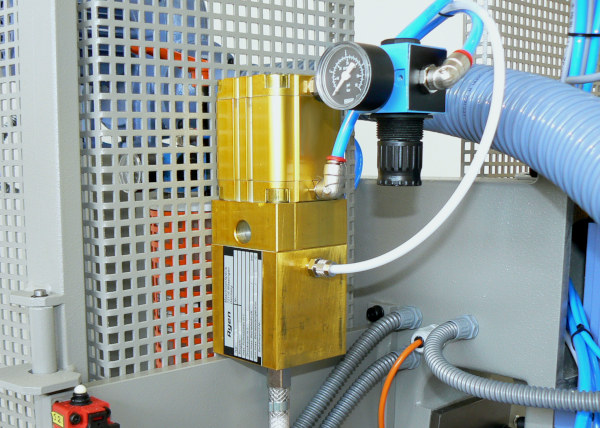

High-pressure gluing system HDL5

The high-pressure gluing sysem HDL5 enables the processing of glues with a viscosity of up to 6000 mPa*s. By increasing the glue pressure, the high-viscosity glue can be processed without any problems. This add-on is particularly necessary when using glues for outdoor use (glue class D4).