Automatic Knot Plugging Machine - Alomat AL310L-A

Alomat AL310L-A at a Glance:

Automatic plugging of wood defects with normal plugs and real knot plugs

Short cylce time of 2.2 s

66 % less energy consumption compared to predecessor model AL100L-A

Operator easily chooses to plug with normal plugs or real knot plugs only by switching the foot valve without further settings

Workpiece clamping by lowering the unit

Workpiece thickness up to 170 mm max.

10 mm clamping stroke

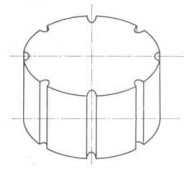

15 mm bis 35 mm plug diameter

7mm, 8 mm or 9 mm plug thickness

Circumferencial gluing of normal plugs by means of glue rising grooves

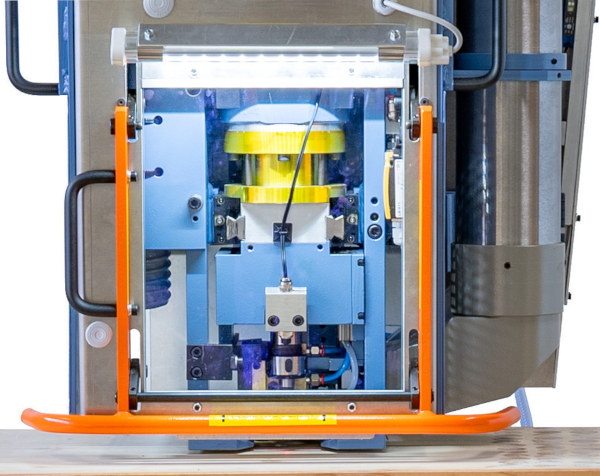

The Alomat AL310 series is the latest development of our proven knot plugging machines. Its speed and precision are unrivaled. With 66 % energy savings compared to the predecessing series, you can work twice as fast: the Alomat AL310L-A's cycle time of just 2.2 seconds speaks for itself! This machine can be used to plug either with real knot plugs or with normal plugs from batten, one after the other, only by choosing the according foot valve.

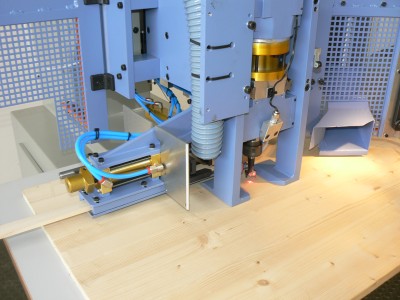

Alomat AL310L-A works with workpiece clamping by lowering the unit. The advantage of this method: The height of the work table is not changed; the operating height always remains constant, regardless of the workpiece thickness. This also allows problem-free processing of long workpieces with a workpiece thickness of up to 170 mm.

During each work cycle, the normal plugs are milled from batten, which is automatically fed. The real knot plugs are automatically fed from the plug container during each work cycle, in which approx. 1000 pieces of Ø 25 mm x 8 mm can be stored.

The plugging depth can either be 7 mm, 8 mm or 9 mm, with the workpiece clamping guaranteeing that the normal plug or real knot plug is pressed in without any protrusion.

Both the clamping stroke and the workpiece thickness compensation are performed from above. For this purpose, the processing slide (incl. drilling and milling unit, glue injection device and feed cylinders) is lowered.

The AL310L-A creates a tight fit of the normal plug by gluing the base and providing circumfrancial gluing to increases the mechanical load-bearing capacity and quality of the workpiece thanks to the enlarged gluing surface. This greatly increases the reliability of the patched areas compared to processes in which only the bottom of the plug is glued. The normal plug is pressed in up to the bottom of the drill hole and lies on the same level as the workpiece surface. This prevents the normal plug from being drawn into the drill hole when the glue diffuses into the workpiece. In addition, no glue pool is created and a volume of air between the normal plug and the base of the drill hole is avoided.

The precise injection of glue prevents an unwanted glue rim, so that the surface of the workpiece remains clean and can be processed immediately.

The glue rising groove depth is adjustable. This ensures that the gluing always withstands the upcoming stress on the workpiece and that your finished wood retains its high quality.

Technical data

Tool drive power

2

kW

Tool drive rotation speed

2000 - 4560

rpm

Feed motor power

0.65

kW

Cycle time

2.2

s

Air consumption per cycle

9

L

Plug diameter

15 | 20 | 25 | 30 | 35

mm

Plug thickness

7 | 8 | 9

mm

Workpiece clamping height

10 - 190

mm

Projection to drill

650

mm

Working table dimensions (width x depth)

1000 x 600

mm

Working height

900

mm

Necessary extraction capacity

360

m³/h

Extraction port diameter

106

mm

Compressed air connection

G 3/8

Compressed air system

6

bar

Operating pressure of glue container

1.5 - 3

bar

Glue container volume

1.4

L

Installation dimension length

1375

mm

Installation dimension width

1000

mm

Installation dimension height

2040

mm

Total machine weight

560

kg

Add-on options for Alomat AL310L-A

Illustrations may differ from the original

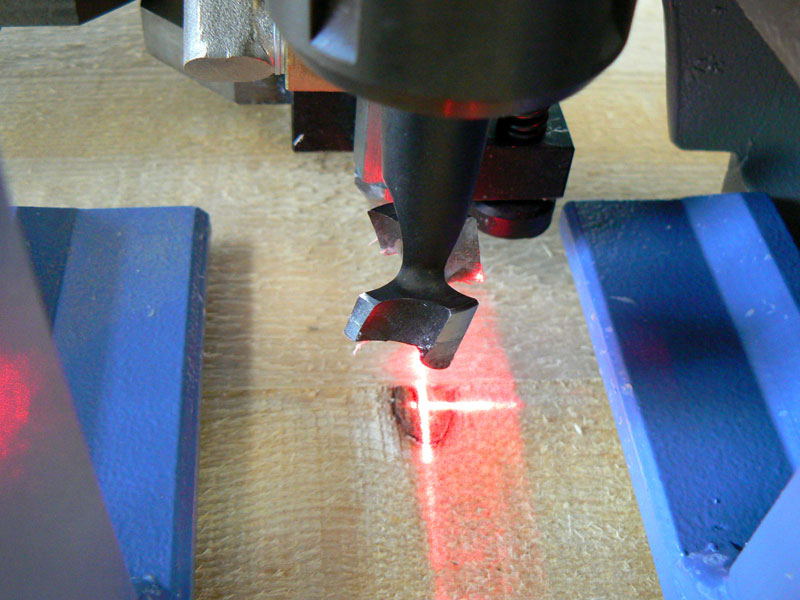

Target light

Our cross laser is used to optimally target wood defects. This means that the knot is in the center of the drill and can be completely replaced by the plug.

Workspace light

Even in poor lighting conditions, the LED workspace light guarantees illumination of the working area.

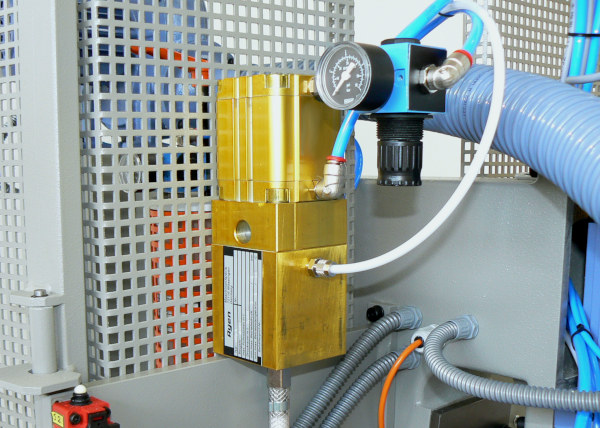

High-pressure gluing system HDL5

The high-pressure gluing sysem HDL5 enables the processing of glues with a viscosity of up to 6000 mPa*s. By increasing the glue pressure, the high-viscosity glue can be processed without any problems. This add-on is particularly necessary when using glues for outdoor use (glue class D4).

Automatic batten feed LZE-100/1

To save time, use our automatic batten feed LZE-100/1 , which greatly reduces the loading time of our automatic plugging machines. The battens required for the production of the normal plugs are kept in stock in the stacking magazine and are automatically separated after each batten ends and pushed to the starting position.

Batten length: 975 mm - 1005 mm

Batthen height: 6 mm - 16 mm

Batten width: 20 mm - 45 mm

Duration for batten change: 6 s

Accessories for Alomat AL310L-A

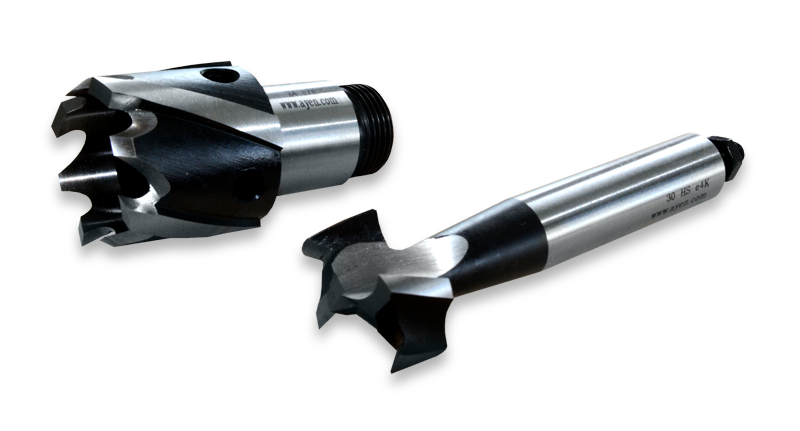

Drilling tool

Tool holder of drill: cylindrical shaft Ø 16 mm with adjustment screw M6 | material HSS

Milling tool

Tool holder of milling tool: M22 x 1,5 | material HSS