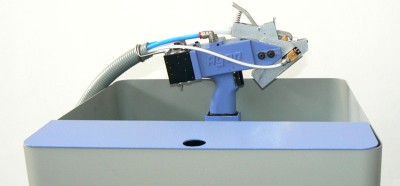

Dowel Inserter - magnum

magnum at a Glance:

Mobile handheld device

Easy Handling

Compact design

Only compressed air required for operation

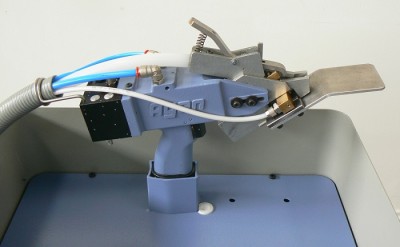

Centering accuracy due to protruding glue nozzle

Glue application always within hole through protruding glue nozzle

Glue quantity, injection timing finely adjustable via valve control block

Choice on insertion gun for “glue + dowel” or “glue only”

Integrated water flushing option

Standard high-pressure gluing system for the use of D4 glue

Allows to work in any position, even upside down

Our experience in the construction of mobile dowel inserters dates back to 1974, when we were awarded the Bavarian State Prize in Gold for the DÜPO TE2-8 machine in 1975. Today, we produce the magnum 6/8 and magnum 8/10 machines as successor models for interior work as well as the magnum 8F for window construction.

In companies of the furniture producing industry, interior design and window manufacturers, where a stationary dowel insertion machine cannot be used due to lack of space, the use of the magnum increases the efficiency of dowel insertion to the maximum. The magnum also allows a wide range of workpieces.

Not requiring an electrical connection, but only a compressed air connection, is one of the major advantages of the magnum compared to other dowel insertion devices. An electronic control system is also superfluous thanks to the countless adjustment options on the valve control block. All these features allow the entire unit to have a compact design; it is lightweight, mobile and quickly ready for use in any corner of your workshop thanks to its compressed air connection.

The standard high-pressure glue container holds approx. 1.4 liters of glue and can process any glue from D1 glue (PVAc white glue) to D4 glue with a viscosity of up to 6,000 mPas. Approximately 10,000 dowels can be glued with the specified amount of glue. At the same time, the glue container is used for water rinsing. With a quick turn of the screw on the valve control block, permanent glue flow or water flow for rinsing the entire gluing system is possible, so that the glue container always remains free of residues and impurities.

The amount of glue to be injected and the injection timing can be adjusted quickly and easily on the valve control block of the glue gun. To save time, the magnum's glue gun also has a selector lever for doweling with glue or just gluing the opposite side, so no additional glue syringe is required. The protruding glue nozzle guarantees precise positioning of the gun (no dowel is missed), and the glue is always sprayed into the hole, regardless of whether it is deflected by contamination of the nozzle.

With the easy-to-use insertion gun, you can insert dowels in any position and even on unstacked workpieces. This means you are independent of the dowel insertion location and workpiece position, and you do not need to make any major preparations before you can use your magnum. The dowels are always supplied individually, i.e. the dowel line is not permanently filled with dowels, but a single dowel is transported and driven in during each dowel insertion process. This means that the weight of gun and dowel line is at manageable 2.4 kg, despite the stable design of the gun. The dowel protrusion can be freely and continuously adjusted between 8 mm and 20 mm (magnum 6/8 and 8/10) or between 11 mm and 25 mm (magnum 8F) via a scale on the dowel insertion gun.

If you use dowels suitable for automatic machines, you can even dispense with a length testing and diameter calibration device. However, we are happy to offer these as accessories if you have other requirements.

The advantages are clearly "in" hand:

No power connection required

Only compressed air connection required for operation

Compact design

Precise positioning of the insertion gun due to protruding glue nozzle

Rapid changeover from the “dowel insertion + glue application” work cycle to the “glue application only” work cycle

Cycle time 1.2 s

Glue container volume 1.4 L; sufficient for approx. 10,000 dowels

Glue amount infinitely variable and finely adjustable

Stacking of workpieces not required

Insertion direction of the insertion gun arbitrary, function independent of position

Low-maintenance glue nozzle with regular cleaning

Integrated water flushing by filling the glue container with water and setting gun for permanent glue flow

Lightweight, ergonomic design of the insertion gun

Rebound-free dowel insertion

Dowel protrusion freely selectable and infinitely adjustable

Dowel lengths 25 to 45 mm (window manufacturer version magnum 8F lengths 30 to 50 mm)

We build the magnum dowel inserter in 2 designs:

- for interior work companies: magnum 6/8 and magnum 8/10

(Devices for processing 6, 8 or 10 mm dowel diameters and 8 to 20 mm dowel protrusion)

- for window manufacturers: magnum 8F

(Device processes 8 mm dowel diameter and ensures dowel protrusion of 11 to 25 mm)

Technical data

Compressed air connection

G 1/4

Compressed air system

6

bar

Air pressure glue, max.

6

bar

Air consumption with continuous operation

200

L/min

Cycle time

1.2

s

Glue container volume

1.4

L

Dowel bunker volume

4

L

Installation dimension width

480

mm

Installation dimension depth

480

mm

Installation dimension height

900

mm

Total machine weight

71

kg

Single gun weight

2.2

kg