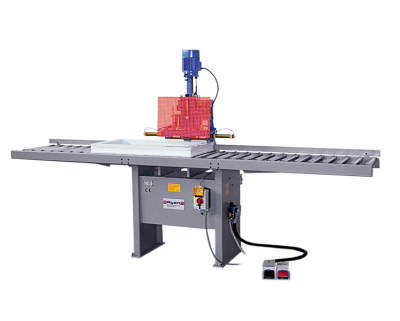

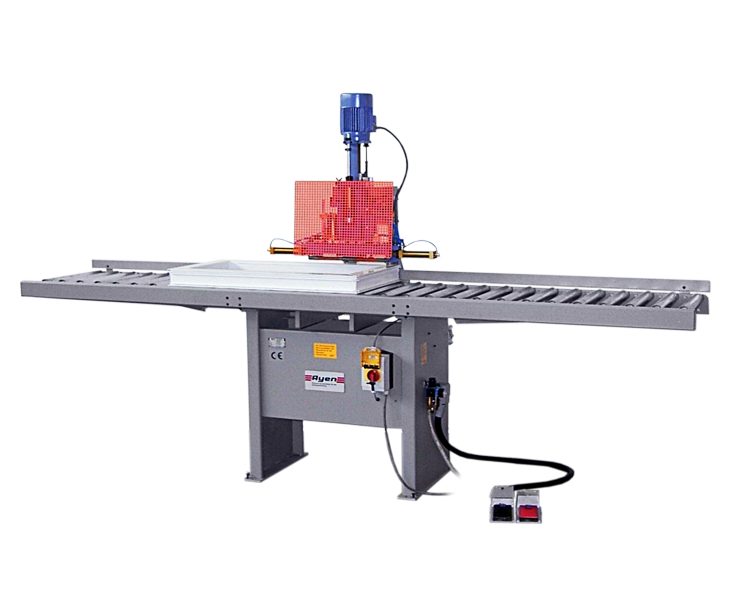

Drilling Machine for Window Fittings - GBM3K

GBM3K at a Glance:

For drilling corner and stay bearings in plastic window profiles

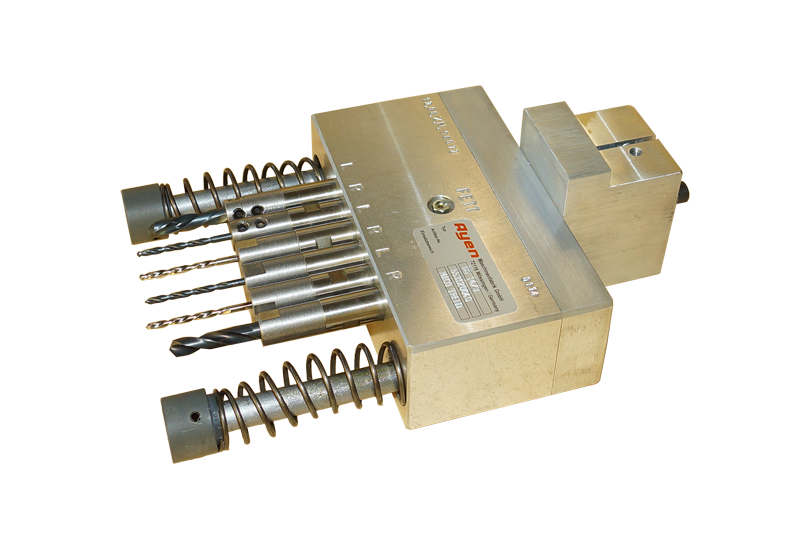

6 drilling spindles

Spindle center distance according to the corner and stay bearing type

Support table 2400 x 460 mm, extendable to 940 mm in depth

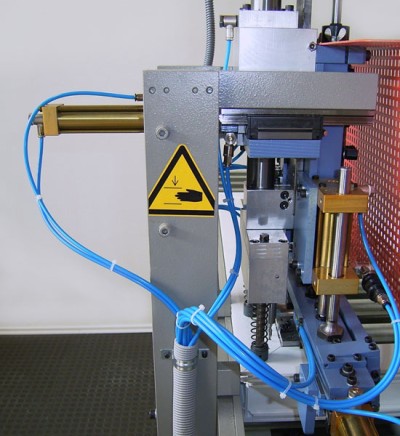

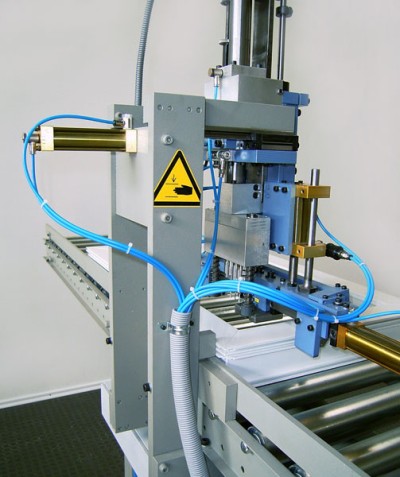

The GBM3K was developed as an easy-to-operate, powerful yet precise and cost-effective machine for drilling corner and stay bearings in plastic window profiles. The GBM3K works with an accuracy of 0.1 mm, while easily positioning even large and heavy window elements on the 2400 mm x 460 mm support table, which can be extended to a depth of 940 mm.

Depending on the type of corner and stay bearing, a special multi-spindle drilling head is used, for example a drilling head with 6 drilling spindles with 16 mm center distance. All holes are drilled in a single work step.

Optionally available:

Roller conveyor instead of plywood support table

Automatic adjustment to profile width

Technical data

Tool drive power

1.1

kW

Tool drive rotation speed

1400

1/min

Drilling spindle number

6

Spindle center distance

16

mm

Air consumption per cycle

5

L

Working table dimension (width x depth | extendable)

2400 x 460 | 940

mm

Working height

880

mm

Compressed air connection

G 1/4

Compressed air system

6

bar

Stop fence

2540

mm

Installation dimension width

2600

mm

Installation dimension depth

800

mm

Installation dimension height

1820

mm

Total machine weight

195

kg