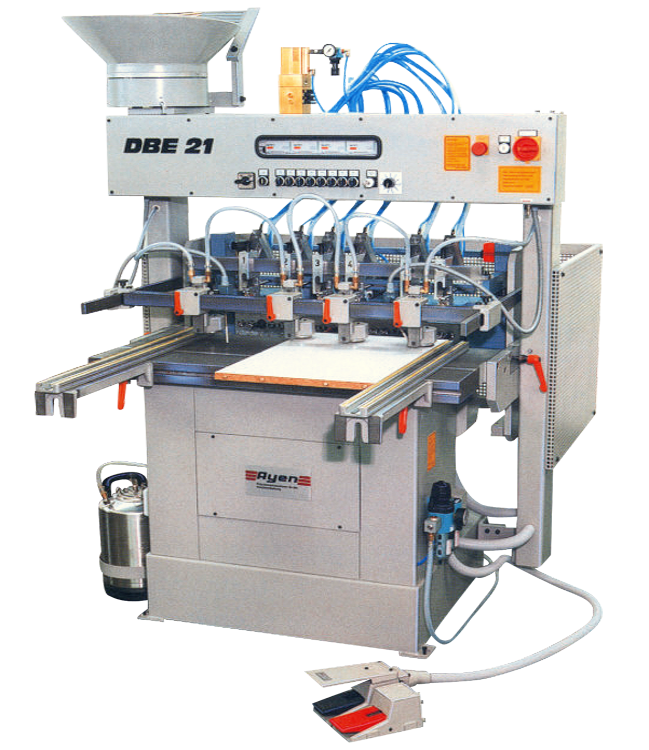

Machine for Dowel-hole Drilling and Insertion - DBE21

DBE21 at a Glance:

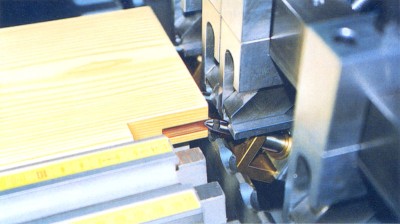

Dowel-hole drilling and insertion in one operation

21 drilling spindles

32 mm spindle center distance

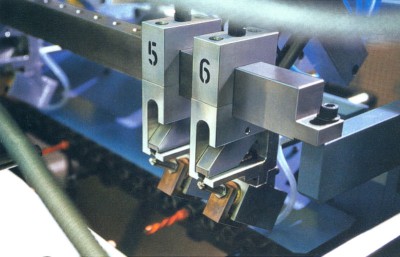

6 standard insertion stations

6 to 12 mm dowel diameter

25 to 45 mm dowel length

5 - 7 s cycle time

DBE21 combines dowel-hole drilling and insertion with maximum precision. With 6 insertion stations as standard and the ability to process 21 dowel holes simultaneously, it is not only suitable for frame parts, but also for panel-shaped workpieces. The PLC-controlled operation, pneumatic workpiece clamping, sensor system, chips extraction and Ayen-proven glue injection with immersive glue nozzles ensure clean and trouble-free work. In addition, two top fences made of anodized, abrasion-free aluminium profiles, which can be moved across the entire machine table or attached to the side of the machine for processing particularly long workpieces, ensure precise alignment of the workpiece.

Program selector switches (drilling only, drilling + gluing, drilling + gluing + dowel insertion, rinsing) allow to turn glue application or dowel transfer on or off in seconds. The high-pressure glue condenser installed as standard and a 7-liter glue container guarantee even glue distribution. In addition, the drilling depth (max. 45 mm) and the dowel projection (8 to 25 mm) can be adjusted with a single move on the DBE21.

If you have any further questions about the function and equipment of our DBE21, please do not hesitate to contact us.

Technical data

Tool drive power

1.5

kW

Tool drive rotation speed

2800

rpm

Drilling spindle number

21

Drilling spindle center distance

32

mm

Number of glue injection/dowel insertion stations

6 | 8

Glue container volume

7

L

Dowel length

25 to 45

mm

Dowel diameter

6 | 8 | 10 | 12

mm

Drilling stroke

80

mm

Drilling depth, max.

45

mm

Height setting drilling beam, max.

40

mm

Working height

800

mm

Working width, max.

640

mm

Workpiece thickness, max.

90

mm

Workpiece width (stop fences parallel)

860

mm

Workpiece width (stop fences lengthwise)

unlimited

mm

Extration port diameter

106

mm

Compressed air connection

G 1/4

Compressed air system

6

bar

Air consumption per cycle

12

L

Installation dimension width

1500

mm

Installation dimension depth

1700

mm

Installation dimension height

1900

mm

Machine total weight

750

kg

Add-on options for DBE21

Additional glue injection and dowel insertion stations

Special spacing of drilling spindels in drilling beam

Differing spindel number in drilling beam

Additional (second) spiral conveyor for second dowel diameter

Automatic compensation for different dowel diameters

Sensor-controlled activation of the glue valves

Additional container for water flushing device

Glue injection and dowel insertion station in slim design

Guide bridge with two or three vertical drilling units

Inclinable drilling beam, adjustable to mitre angle between 0° and 45°

Vertical drilling unit

We are happy to build your DBE21 according to your wishes.

Accessories for DBE21

Mitre angle for frame mitres

Stop fence setting gauge