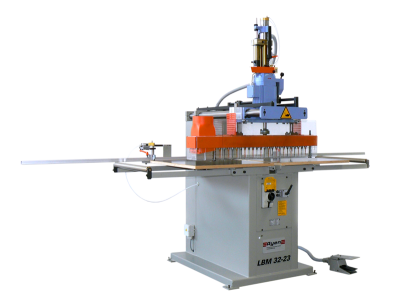

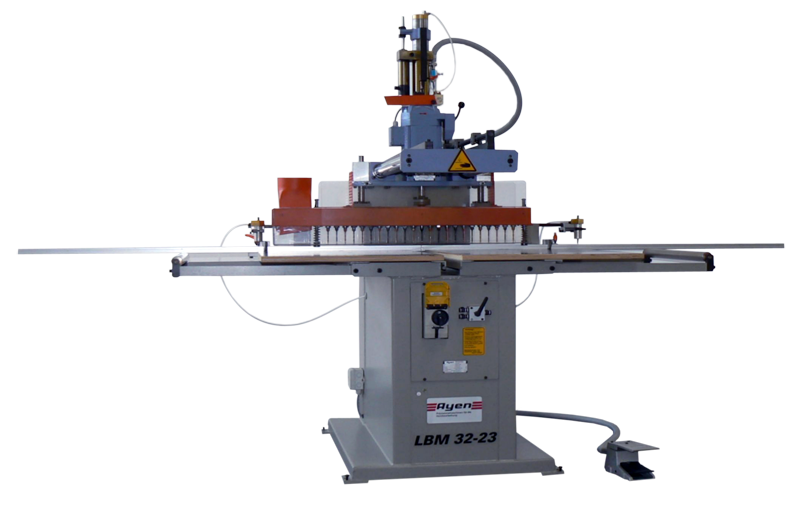

Drilling Machine for Hole-Series - LBM32-23

LBM32-23 at a Glance:

23 drilling spindles

32 mm spindle center distance

3000 mm stop fence

Drilling unit on load-bearing shafts via linear guides movable

Oil brake as standard

Support rollers can be folded down

The LBM32-23 is the precise and versatile drilling machine for interior work companies drilling hole-series, semi-open connecting fittings and hinges.

There are two basic solutions for drilling hole-series, connecting fittings, etc.:

If it is a machine with a fixed-position drilling beam, the workpiece must be moved by hand to achieve the correct position in relation to the drilling beam so that the hole-series can be drilled. The disadvantage: very large workpieces have to be moved manually. This additional work is strenuous, harmful to health, time-consuming and furthermore exposes the workpiece surface to unnecessary stress. Damage due to scratching is possible with this kind of machines.

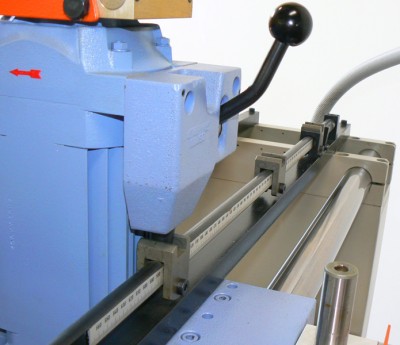

Our LBM32-23, on the other hand, has a depth-adjustable carriage that carries the drilling unit with drilling beam and can be moved manually on two load-bearing support shafts. The carriage can be precisely engaged at the desired distances for drilling using grid cams. This functional principle has two fundamental advantages: firstly, it ensures that two or three rows of holes are arranged absolutely parallel, and secondly, the workpiece hardly needs to be moved, which saves muscle power and avoids scratches on the workpiece. An optionally attached contact pressure finger can also secure the workpiece against the stop rail.

The oil brake cylinder fitted as standard for tear-out free drilling allows rapid traverse of the drill beam up to the workpiece surface (time saving) and then controls the feed speed during drilling.

The advantages are obvious: with the LBM32-23, you can drill all holes quickly, precisely, gently, with little effort and faultless.

Technical data

Tool drive power

2.2

kW

Tool drive rotation speed

2800

rpm

Drilling spindle number

23

Spindle center distance

32

mm

Drilling slide movement distance

630

mm

Drilling stroke

98

mm

Oil brake stroke

70

mm

Working table dimensions (width x depth)

920 x 700

mm

Working height

800

mm

Air consumption per cycle

3

L

Compressed air connection

G 1/4

Compressed air system

6

bar

Installation dimension width

1300

mm

Installation dimension depth

970

mm

Installation dimension height

1850

mm

Total machine weight

330

kg

Accessories for LBM32-23

Order no.

Description

562 + 563

Special grid device, pneumatic

564

Grid slider for drilling hole-series, manually operated

565

Casters for machine

566

Pressure cylinder with immersible contact pressure finger

570

Drill extension M10, right (2 pieces included in standard equipment)

460.31

Stop fence extension 1000 mm (additionally required for this: 464.13)

464.11

Stop slide (1 piece included in standard equipment)

464.12

Stop slide couple (1 couple included in standard equipment)

464.13

Coupling slider for stop fence extension 460.31