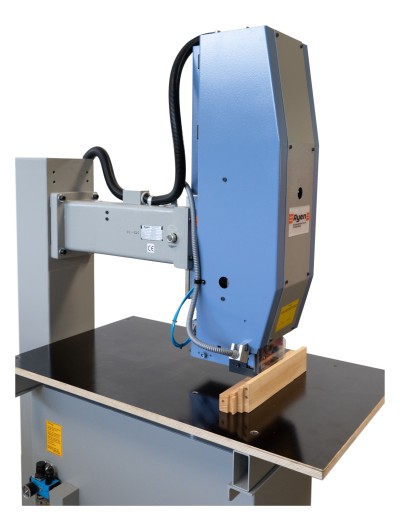

Boom Milling Machine - ABMP66-L

ABMP66-L at a Glance:

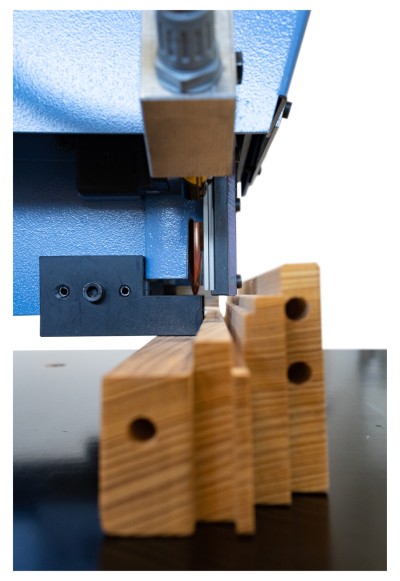

For milling out pitch pockets or other defects in the rebate

Robust and fuctional construction

With pneumatic feed and workpiece clamping

720 mm projection

120 mm height adjustment of the drilling unit

Plugsize G2

With machine frame

ABMP66-L boom milling machine has been specially designed for the daily requirements of interior work companies. It has the robust and well thought-out design typical of Ayen and is beyond this easy to operate.

ABMP66-L has a single-spindle milling head and a standard dust extraction hood, which ensures a clean workplace. The milling stroke is pneumatically operated, its milling feed cylinder also utilized for the workpiece clamping. The machine has a large projection of 720 mm to the cutter which is large enough for two-sided processing of especially wide workpieces. Targeted by the line laser no wood defect can be missed. It can mill out pitch pockets of size G2 as standard. We are also happy to convert it for other patch sizes on request.

By using a handwheel the milling unit can be adjusted in its height over a 120 mm range. This makes the ABMP66-L the ideal boom milling machine for companies that want to combine high demands with easy handling and low costs.

Technical data

Tool drive power

1.5

kW

Tool drive rotation speed

2800

rpm

Tool drive rotation speed cutter

4000

rpm

Pojection to motor spindle

660

mm

Projection to cutter

720

mm

Height adjustment via hand wheel

120

mm

Milling stroke

15

mm

Working table dimensions (width x depth)

600 x 1000

mm

Working height

920

mm

Extraction port diameter

63

mm

Installation dimension length

1170

mm

Installation dimension width

600

mm

Installation dimension height

1950

mm

Total machine weight

175

kg

Plug sizes

G2 | G22