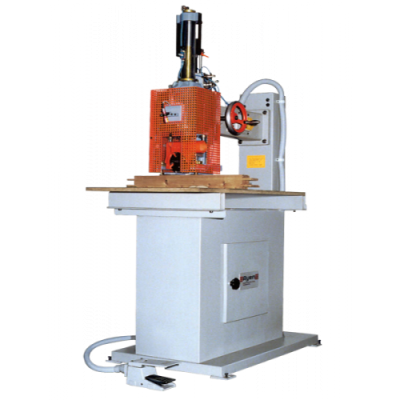

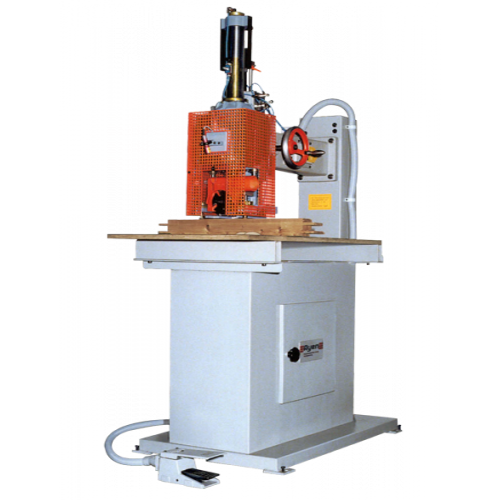

Boom Milling Machine - ABMH66-F

ABMH66-F at a Glance:

For milling out pitch pockets

Robust and fuctional construction

720 mm projection

120 mm height adjustment of the drilling unit

With hand lever of pneumatic feed

For wall installation or with machine frame

ABMH66-F boom milling machine has been specially designed for the daily requirements of interior work companies. It has the robust and well thought-out design typical of Ayen and is beyond this easy to operate.

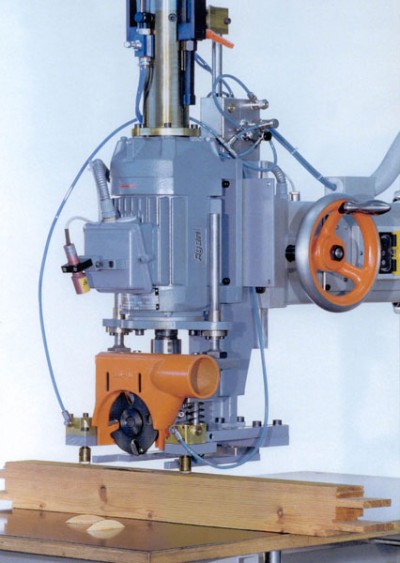

ABMH66-F has a single-spindle milling head and a standard dust extraction hood, which also serves as the workpiece clamping device. It also has a large projection of 720 mm to the cutter which is large enough for two-sided processing of especially wide workpieces.

The machine can either be mounted directly on the wall of your workshop or on a stable machine frame. In addition to the standard hand lever operation, the drilling stroke can also be optionally equipped with a pneumatic drill feed cylinder (ABMP66-F). The height of the milling unit can be adjusted over a 120 mm range using a handwheel. This makes the ABMH66-F the ideal boom milling machine for companies that want to combine high requirements with easy handling and low costs.

Technical data

Tool drive power

1.5

kW

Tool drive rotation speed

2800

rpm

Rotation speed milling spindle

4000

rpm

Maximum workpiece thickness

150

mm

Projection to motorspindle

660

mm

Projection to cutter

720

mm

Height adjustment via hand wheel

120

mm

Cutting stroke

98

mm

Working table dimenstions (width x depth)

400 | 600 x 1000

mm

Working height

855

mm

Necessary extraction capacity

480

m³/h

Extraction port diameter

86

mm

Weight of machine

55

kg

Weight of frame

120

kg

Add-on options for ABMH66-F

Illustrations may differ from the original

Machine frame

If the boom machine is not to be attached to the wall, we will be happy to supply a suitable machine frame:

with/without working table

with/without fence system (1 x depth-adjustable, 2 x side-adjustable)

Target light

Our cross laser is used to optimally target wood defects.

Casters

To save space, you can add casters to your ABMH66-F machine frame. This allows you to push the machine to the operation site.