Boom Machine / Knot-hole Drilling Machine - ABMH66

ABMH66 at a Glance:

Universally applicable

For drilling knotholes

For milling normal plugs and cutting out pitch pockets (optional)

Robust and fuctional construction

660 mm projection

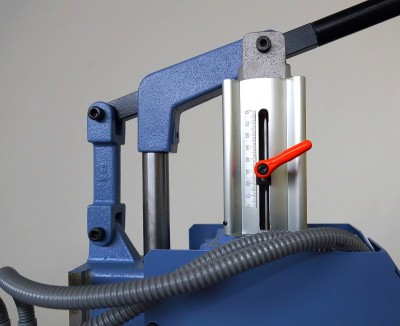

120 mm height adjustment of the drilling unit

With hand lever of pneumatic feed

For wall installation or with machine frame

Individually configurable thanks to extensive accessories

Versatile drill head selection

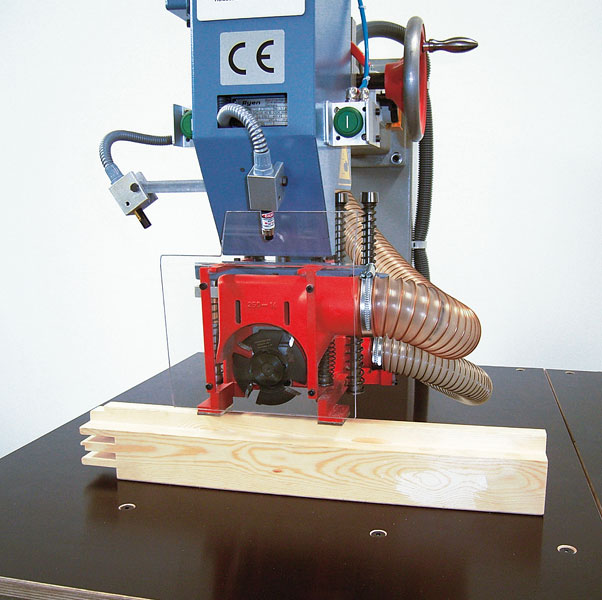

Our Alround Talent ABMH66 boom machine is ideal for interior work companies. It is universally applicable and has the robust and well thought-out design typical of Ayen.

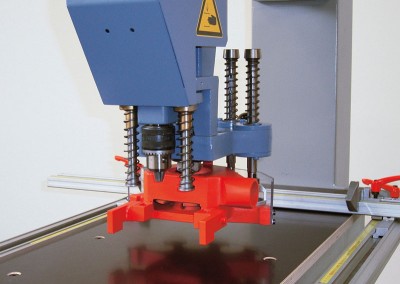

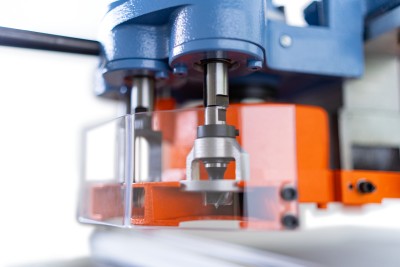

With the standard 4-fold drill spindle swivel head, you can attach 4 different drills or milling cutters, eliminating time-consuming tool changes. A pitch pocket milling head, window handle drilling head, row of holes drilling head or other special drilling heads can be installed via a mounting plate to extend your range of applications.

ABMH66 can be wall-mounted in your workshop or delivered with a machine frame. In addition to the standard hand lever operation, the boom machine is also available as ABMP66 with pneumatic feed. The height of the drilling unit can be adjusted within a 120 mm range using a handwheel.

Whatever your area of application is, we are sure to find the right ABMH variant for you...

Have a look at the product pages of our boom machines ABMH66-B for pure drilling, pure milling (ABHM66-F), our ABMH66-DG swivel joint version for wall-mounting or the ABMP66-L special version for pitch pocket milling.

Technical data

Tool drive power

1.47

kW

Tool drive rotation speed

2800

rpm

Maximum workpiece thickness

200

mm

Projection to drill

660

mm

Height adjustment via hand wheel

120

mm

Drilling stroke

70

mm

Working table dimensions (width x depth)

400 | 600 x 1000

mm

Working height

855

mm

Necessary extraction capacity

110 - 480

m³/h

Extraction port diameter

45

mm

Weight of machine

53

kg

Weight of frame

120

kg

Add-on options for ABMH66

Illustrations may differ from the original

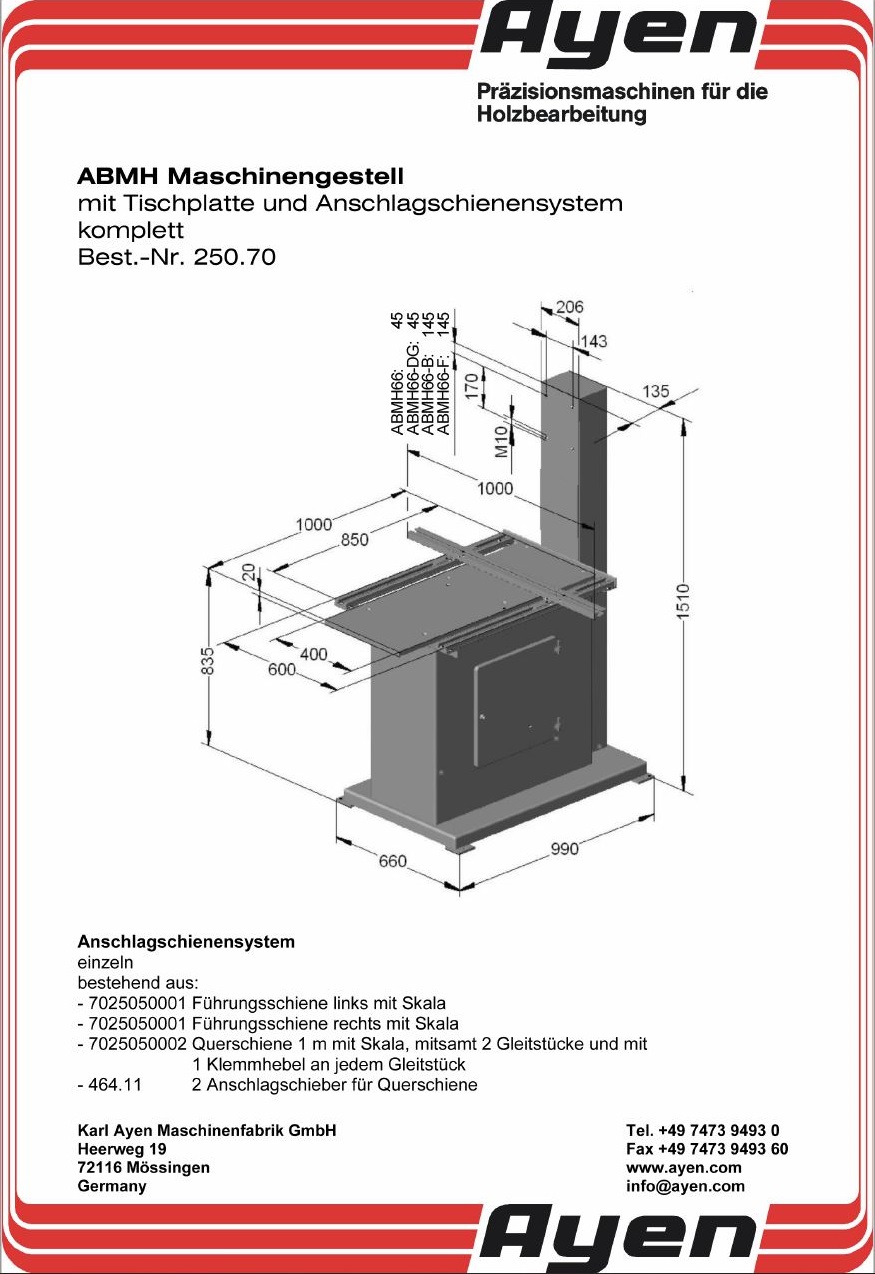

Machine frame

If the boom machine is not to be attached to the wall, we will be happy to supply a suitable machine frame:

with/without working table

with/without fence system (1 x depth-adjustable, 2 x side-adjustable)

Target light

Our target lights are used to optimally target wood defects:

Cross laser

When drilling: for point-shaped wood defects, such as knots

Line laser

When milling: for elongated wood defects, such as pitch pockets

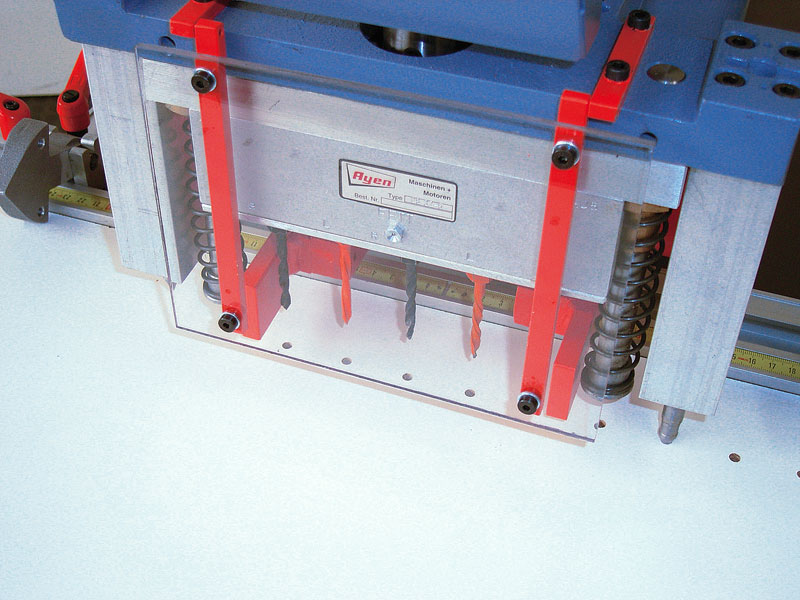

Multi-spindle drilling heads

If you make rows of holes, mount fittings or are in need of custom drilling pattern, we can certainly help you, for example with our 5-fold cc32 drilling (see illustration on the left).

Casters

To save space, you can add casters to your ABMH66 machine frame. This allows you to push the machine to the operation site.

Two-hand release

To prevent injuries, a two-hand release using two push buttons can be installed for the pneumatic version of ABMH66.

Accessories for ABMH66

Drill bits (knot hole drill bits with or without depth adjuster)

Cutter (to produce normal round plugs)

Pitch pocket cutter (to cut out pitch pockets)